Building The Grand Egyptian Museum

FreeExplore Africa’s largest museum and the challenges faced in constructing this unique development.

On 1 November, the Grand Egyptian Museum (GEM), said to be the largest museum dedicated to a single civilisation, was officially opened to the public in Egypt.

The museum complex covers a total estimated land area of 490,000 square metres, with a total built-up area of 167,000 sq m, situated about a mile away from the ancient pyramids of Giza. It houses almost 20,000 artefacts of ancient Egyptian civilisation.

GEM was built by a team of Egypt’s Orascom Construction and Belgium’s Besix over a period of more than 10 years, with the groundbreaking ceremony completed in 2002.

The complex is divided into four basic categories – exhibition galleries, conference centre, landscaping areas, commercial retail and restaurants. It also hosts temporary exhibition galleries and special exhibitions, a children's museum, a 3D experience and large-format screens with a total floor area of 32,000 sq m.

A separate exhibition is dedicated to the 4,500-year-old King Khufu solar boat, which is considered the oldest boat in the world. The conference centre is situated inside the main complex and contains an auditorium with 1,000 seats, three 250-seat seminar rooms, gallery space, meeting rooms, a business centre and press room.

The largest part of the museum is designed to host a variety of outdoor activities through an open-air space system comprising a piazza, an open-air exhibition, Dunal Park, Nile Park, recreational garden, temple garden and Land of Egypt Park. Additionally, GEM houses several support buildings and structures that include a multi-function parking complex, a ticketing building and an accessible Pyramid Climb that overlooks the desert land and the Giza Pyramids.

Construction of the museum was carried out despite extraordinary challenges such as the economic crisis and Covid-19 pandemic, and reached over 120 million manhours, coordinated through advanced building information modelling (BIM), and the collaboration of more than 300 partners and suppliers. The Besix-Orascom Construction team was responsible for the full scope of construction, including structural works, finishing, advanced mechanical, electrical and plumbing (MEP) and ICT systems, fit-out and secure environments for artefact preservation.

The architect was Ireland’s Heneghan Peng, which formed a joint venture with Arup and Buro Happold to develop the design, expanding to include UK-based Cultural Innovations and Metaphor for museological services and the Netherlands' West 8 for landscape design.

GEM’s engineering highlights include the fact the building is composed almost entirely of triangles – an architectural homage to the pyramids – and with nearly no right angles. The building also features 25-metre-high ceilings, 20-metre cantilevers and a double-glazed facade with prestressed vertical cables – a first in Africa.

In terms of architecture, beginning at a focal point outside of the entrance, the museum structure radiates outward toward the pyramids along a visual axis that aligns directly with the positioning of the three pyramids. The interior walls follow these radial lines to create a fanning shape, with the roof sloping upward along a similar visual line to meet the highest point of the pyramids but never surpassing them.

The six-storey grand staircase functions as a chronological route to guide visitors to the different galleries and the entrance to the permanent exhibitions is located at the top of the staircase, with visitors completing their experience with the view of the pyramids. Many of the largest and heaviest artefacts are placed upon the staircase at varying levels.

The site also includes extensive gardens that provide public green space for the local community. Developed in collaboration with landscape architecture firm West 8, the gardens were designed to tell the story of the Nile floodplain that once allowed the stones for the pyramids to be transported by ship. This open zone reveals the museum in its full 800-metre length and houses 5 hectares of outdoor exhibition space to be populated by artefacts.

In addition to the public-facing galleries, GEM hosts a conservation centre, laboratories and storage facility connected to the main building via a tunnel, which is one of the largest in the world with 17 different labs dedicated to preserving the museum’s artefacts.

GEM is also the first green museum in Africa and the Middle East, having earned the Edge Advanced certification for green buildings in February 2024.

The museum employs an intelligent energy management system that includes the use of solar panels, low-consumption LED lighting systems and natural ventilation techniques, contributing to energy savings of 62% compared to conventional standards, along with a significant reduction in carbon emissions. The structure is largely made of concrete to reduce variation in temperature and minimise the need for air conditioning in such a vast space.

The development also uses advanced rainwater harvesting and reuse for irrigation, alongside water-saving fixtures and smart irrigation techniques. It includes green spaces for air purification and cooling systems based on ancient Egyptian ventilation, integrated with modern technologies, using Egyptian marble and granite from the local environment.

“From a strong architectural concept, a clever and multi-layered museum campus was born that today is able to host millions of visitors,” said Adriaan Geuze, founder of West 8. “The grandeur of both the legacy and scale of the buildings has been elegantly merged into the edge of the Giza plateau. This delivered a museum that is truly embedded in the historical and geological context.”

In an exclusive interview, the museum’s contractors Besix and Orascom Construction told ConstructAfrica about the challenges faced in delivering the project and how they were overcome.

Q) What were the challenges the museum’s unique design presented for the contractors and how they were overcome?

The [museum’s] triangular geometry and absence of right angles meant every component in all trades (structure, architecture and MEP) was unique, resulting in no repetition. We relied on advanced BIM to coordinate hundreds of partners and achieve millimetric precision. For example:

- We designed and installed a 3D folded concrete roof slab spanning up to 40 metres with custom formwork. The 30,000 sq m triangular roof in white concrete illustrates the high level of precision that was required; every formwork line had to align seamlessly with the marble joints on the floor and the ceiling tiles above, a continuous stretch of nearly 1km without a single right angle!

- We engineered Africa’s first prestressed cable-supported facade to maintain structural integrity

- Digital tools allowed real-time clash detection and sequencing, ensuring perfect alignment with the pyramids.

Q) The museum is called a masterpiece of engineering complexity. What were some other engineering challenges that were faced during its construction?

Several challenges stand out:

- Designing and installation of the 40 metres 3D concrete roof slab

The folded roof is considered the roof of both the museum and conference centre buildings (where it is a concrete structure) and also the roof for the entrance court, food court and Temple Garden (where it is a steel structure confined between top and bottom perforated aluminium mesh panels).

The concrete folded structure is divided into six bands in each building covering the area between digital stream walls, which are radially aligned concrete walls from the foundation level aligned with the main building’s radial axes. Each band of the folded roof is supported on the digital stream walls from the west side and steel posts from the east side, creating between them windows allowing natural lighting for the main galleries. This makes the folded roof like a sawtooth structure in the east-west direction. Additionally, the roof structure is folded into irregular peaks and valleys along the north-south direction.

The levels and dimensions of the concrete folded roof were based on several equations considering radial and chronological grids. These equations were used to verify the concrete revit model, concrete dimension drawings and, accordingly, the form work drawings/coordinates.

Several studies were done on the concrete mix to achieve the design strength (50 MPA) with white concrete mix achieving the required workability to avoid segregation with the severe inclination of the roof structure.

- Stiletto wall

The same complicated design applied to the stiletto wall, which is composed of 23 modules of different heights ranging from 14 metres to 35 metres and different inclination degrees. During its construction and to overcome the complexity, critical decisions regarding the inclined scaffolding, the installation method whether bottom up or top down as well as the method of picking up stone of a minimum weight of 60kg were taken.

- Massive cantilevers extending 20 metres and ceilings reaching 25 metres in height

- Finalising the structural works above and around the 11-metre Ramses II statue

- Relocating the Khufu solar boat, transported 8.5km and lifted 30 metres into the building with millimetric accuracy

One of the most iconic highlights and challenges at GEM involved the relocation of the 44-metre-long wooden Khufu solar boat in a hermetically sealed, climate-controlled and specially constructed steel container. This was transported on imported specialist multi-wheeled equipment from the existing solar boat museum building adjacent to the Giza pyramids to the GEM site and a new dedicated solar boat building constructed around it.

- Integrating and coordinating over 30 MEP and ICT systems within a structure with no parallel axes

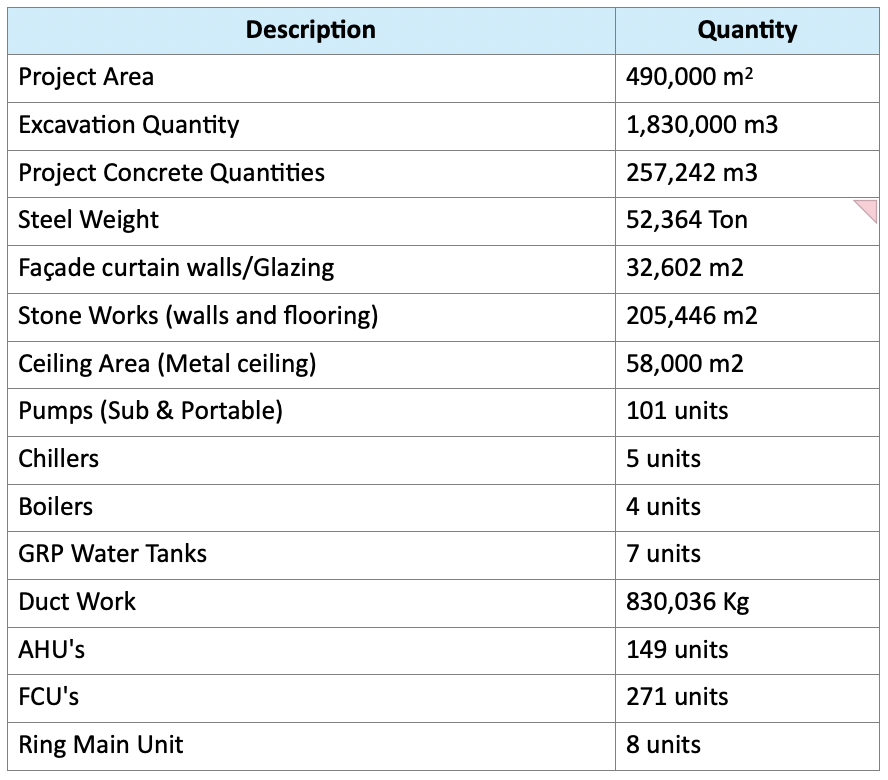

Each required exceptional logistics, structural and architectural solutions. Project key quantities reflect the challenges:

- Onyx facade

Another major challenge was the translucent onyx facade. Since onyx deteriorates when exposed to open air, we worked with the client to design an innovative system that encased it within thin glass panels. This technique was later reused for other museums such as the Guggenheim in Abu Dhabi, scheduled to open in 2026. Projects like these drive us to create materials that didn’t exist before, advancing hand-in-hand with suppliers and subcontractors in constant dialogue.

Q) The museum’s construction spanned more than 10 years, overcoming challenges from financial crises to a global pandemic. How did Orascom and Besix handle these challenges?

The project spanned more than a decade and required particularly strong project management to overcome multiple challenges including global disruptions like the pandemic. We adopted phased delivery, enabling early installation of artefacts while construction continued. Remote coordination tools and advanced digital modelling helped us maintain progress by navigating us through the complexity.

In addition to the renowned Belgian diplomacy and persistence, a key success factor was the excellent complementary collaboration between the joint venture: Besix brought the international expertise in managing complex projects, while Orascom contributed invaluable local knowledge and resources. This partnership ensured continuity and resilience throughout the process.

Q) Advanced BIM modelling was used during construction. Tell us how this technology helped during construction and its potential for other projects.

GEM was in 2012 one of the first projects where BIM was used 100%, allowing us to coordinate the work of 300 subcontractors and companies, and avoid clashes between the over 30 MEP and ICT systems. Now, BIM has become standard on most of Besix and Orascom construction sites.

[For GEM,] we worked on Autodesk’s BIM 360 platform. This allowed us to manage complex geometries and sequencing tasks like roof slab alignment, detect clashes and reorganise the design in time.

For example, [BIM was used] to reroute pipes if they were causing clashes with other infrastructure pathways such as cable trays or ducts and to align all the joints in the stone floors and stone wall cladding with the ceiling pattern. Besix has won the Autodesk Excellence Award for Best Construction Project for its work on GEM.

Top photo: Grand Egyptian Museum (Source: Heneghan Peng)

Discover

myConstructAfrica

Your one-stop-shop for information and actionable intelligence on the construction and infrastructure pipeline in African countries

- News, analysis and commentary to keep up-to-date with the construction landscape in Africa.

- Industry Reports providing strategic competitive intelligence on construction markets in African countries for analysts and decision-makers.

- Pipeline Platform tracking construction and infrastructure project opportunities across Africa from conception to completion.

- Access to contact details of developers, contractors, and consultants on construction projects in Africa.

- News and analysis on construction in Africa.

- Industry Reports on construction markets in African countries.

- Pipeline platform tracking construction and infrastructure projects in Africa.

- Access to contact details on construction projects in Africa.